How to be reactive in case of deviation, non-compliance and product returns ? How to follow and to control your raw material, semi-finished and finished products stocks by taking into account the quality constraints?

Are you at full performance ?

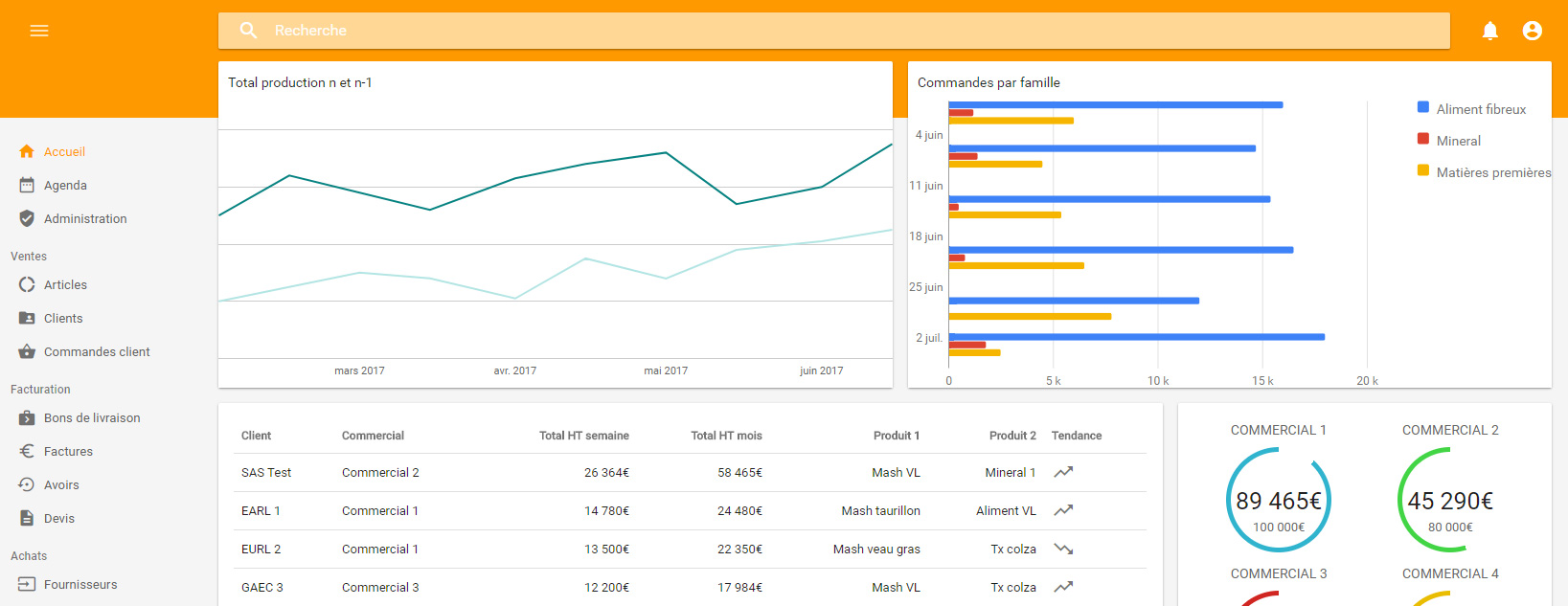

Do you have a 360° vision of your activity ?

Can you track your performance, production or quality indicators ?

Quality management

- Set and follow the cleaning schedule and the timing requirements for zero points.

- Follow-up of the customer and supplier complaints, the implementation of the preventive and corrective actions for the evaluation of their efficiency.

Facilitate the recording of the data and their historisation to manage quality audits. - Configuration of the software with best practices RCNA and GMP to accompany you in your advances. MixSuite comes built-in with the industry standard for quality management to support your requirements.

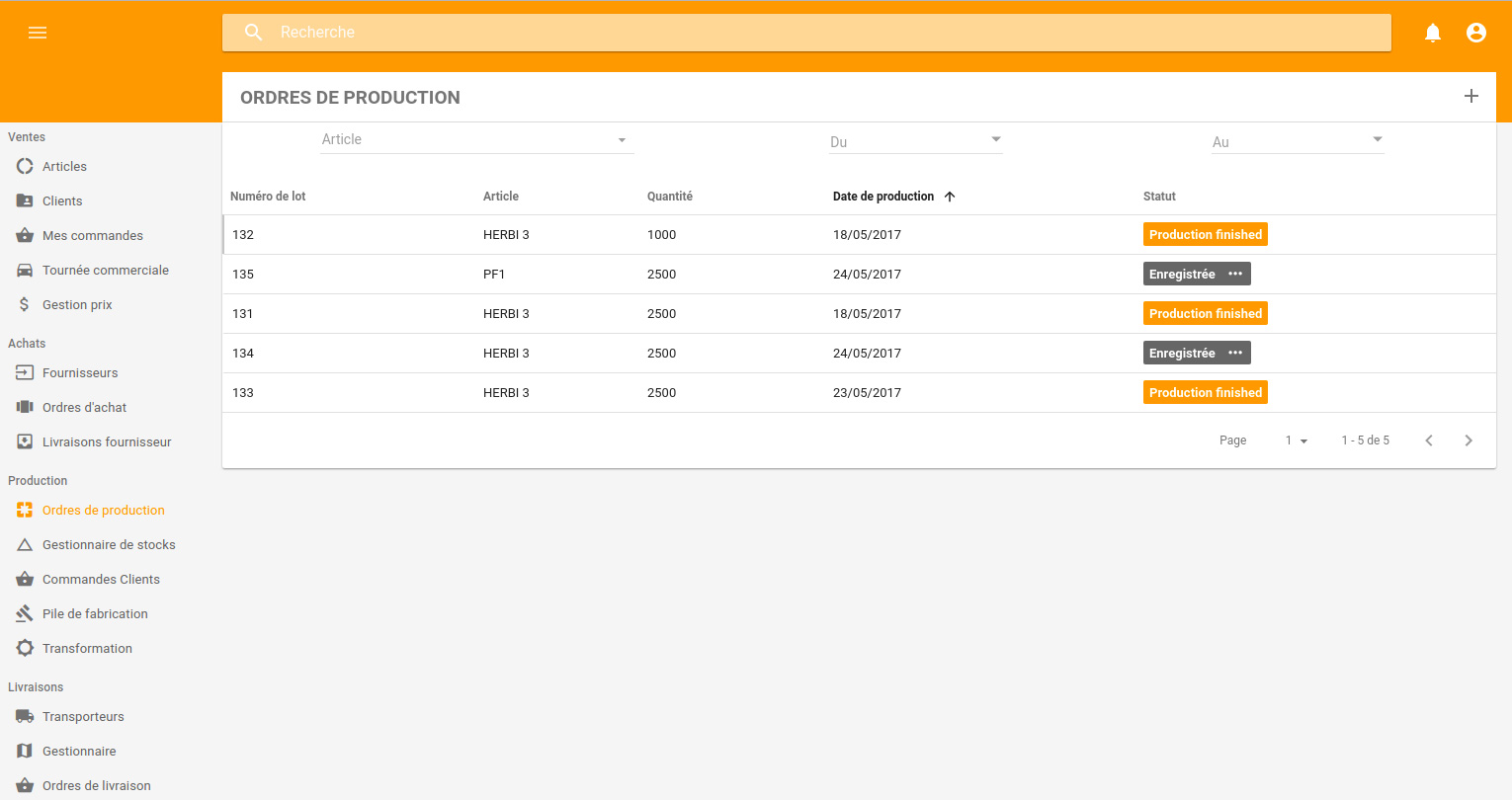

Production management

- How to optimize the scheduling of production orders?

- How to improve the utilization rate of production tools?

- How to follow the production in real-time?

- Configuration of the tools of processing (lamination, flaking, …), of production (factory constraints, incorporation) and of packaging.

- Integration of stock rules in the inventory management (silos, boxes, flat storage).

- Follow-uo of stocks and calculation of forecast stocks and the total cost of work-in-progress.

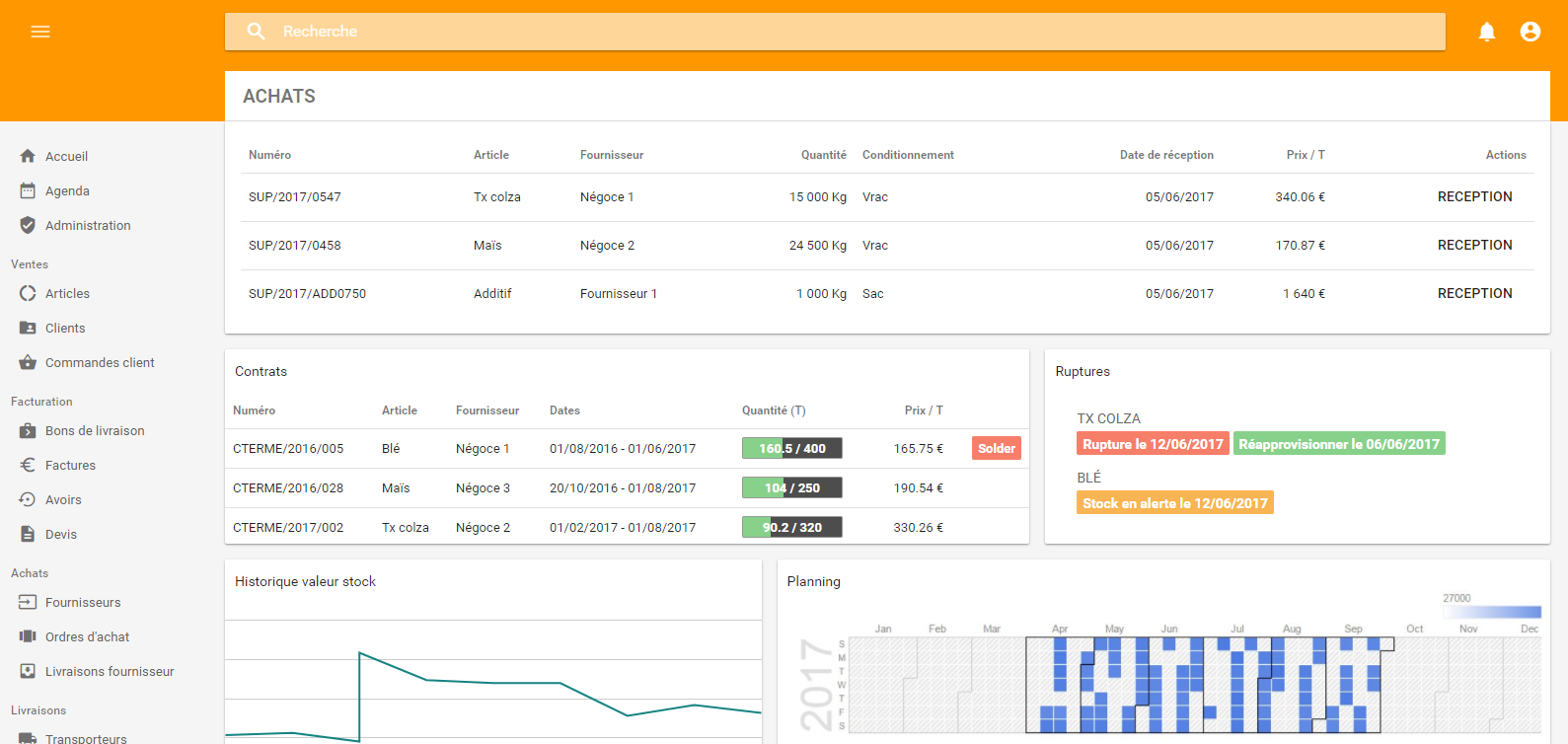

Supply management

What tools to measure the performance of the buyers and the suppliers ?

- Verification of carrier safety certification through integrated databases.

- Monitoring of sampling and analysis of raw materials.

- Management of purchase contracts and valuation of the stock.

- Automate replenishment orders based on forecast inventory

Formulation

- Track the formulation, the constraints, the capacities of bulk mixers and quality control of the inputs.

- Improved management for personalized formulation.

- Handles raw material substitutions and the incorporated quantity.

- Built-in integration for most of the standard formulation softwares.

MixSuite Gear

- LThe traceability secured from the production line.

- With MixSuite Gear – no more human error, the quality of information is ensured.